| Unit | Specifications | |

|---|---|---|

| Work Table (LxW) | mm | 600 x 300 |

| Table travel (X) | 450 | |

| Table travel (Y) | 350 | |

| Servo travel | 345 | |

| Electrode Guide Travel (Z-axis Travel Included) | 350 | |

| Distance between Platen & Table | 375-25 | |

| Working Fluid and Capacity | L | 45L |

| Max. Workpiece Weight | kgs | 450 |

| Machine Weight (net) | 1350 | |

| Power Source | V | 220/380 415/440 |

| Max. Power Consumption | KVA | 4.5 |

| Max. Machining Current | A | 50 |

STANDARD ACCESSORIES

- Filter

- Stainless Water Tank [with Detached Flushing Pump (Made in Japan)]

- Tool Box

- Electrode Guide Ø1.0mm

- Precision Electrode Holder Ø0.1~3.0mm

- Electrode Tube Ø1.0mm

- Calibrating Rod Ø6.0mm

- Halogen Work Lamp

- Leveling Pad

- X, Y-axes Linear Scale (5u)

- X, Y, W-axes Ball Screw

OPTIONAL ACCESSORIES

- Filter

- LED Lamp

- Electrode Guide

- Electrode Tube

- ER Type Precision collet holder: Ø6.35mm

- ER-Precision Adapter

- Rotary Axis:B-axis(Submerged) with Control System

- 80L Stainless Water Tank

- Stainless & Submerged Work Tank & Dieletric Tank

- W-axis optional: W-axis(500mm)+Z-axis(350mm) (Available in SD300, 350, 400, 450, 550, 600, 755)

- Z-axis optional: Z-axis(500mm)+X-axis(500mm) (Available in SD550, 600, 755)

- Finish Stop Device

- Industrial grade micro-processor. X, Y-axis are fitted with linear scales with h5 um resolution. Z-axis is equipped with an encoder with 5 um resolution.

- The machining circuit is driven by high speed, voltage-resistant and current-resistant MOSFET control.

- Intelligent deep hole machining is easy to set by simply entering machining current and the other machining parameters will set automatically.

- Capable of machining super hard alloy in irregular, spherical and curved shapes.

- Job finish stop device increase convenience of operation.

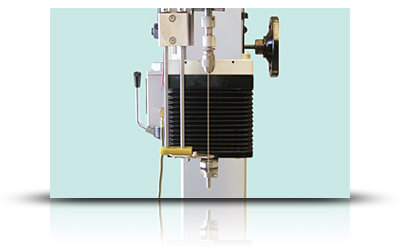

CNC EDM Drilling

- 12.1" TFT LCD display panel.

- PC based controller for cnc drilling edm.

- Use friendly and compatible.

- Auto electrode compensation when machining a hole, the electrode is over.

- 4 axes close loop control.

Automatic tool changer & intelligent tool compensation

- Auto tool changer.(OPT)

- Auto compensating of exchanged new electrode during machining, Electrode is finished.

- When the preset depth is reached, electrode automatic detecting and be risen to workpiece surface.

- Variable depth control of machining.

- Simulation and working path display.

- 100 condition files, each file store 100 sets of data.

- 100 sets of drilling depth.

Flexible & maintainable

- System self diagnosis display.

- Hardware status display.

- Alarm history management.

- PLC ladder on line monitor.

- RS 232 transfer function.

- Chinese/ English conversion.

Dialogue programming

- G/M code programming.

- Background editing.

- Special modular machining ( circle rectangle pattern).

- Auto edging, center of two points, center of circle including electrode radius compensation.